When a Hot Tap is Turned On

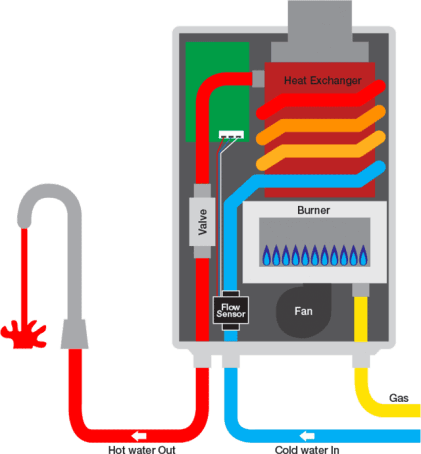

As soon as a hot water tap or shower is opened, water enters the sealed combustion chamber of the continuous flow unit. Flow sensors within the advanced computerised control system detect the water flowing through.

Highly precise flow sensors detect water movement through the system within seconds of a hot tap or shower being activated. These advanced metering devices feed data in real-time to the smart control module. This begins processing incoming readings to prepare the burner for ignition as flow rate increases.

Some continuous flow models even utilise multiple sensors to accurately account for pressure losses at different flow velocities. This enhances the precision of water temperature control across varying output demands. The instant detection of flowing water initiates the seamless process for delivering a reliable stream of heated water in line with temperature settings.

Igniting the Burner

Upon detecting water flow, the digital control board activates the automatic ignition sequence to fire up the gas burner or electric heating element. State-of-the-art control circuitry monitors the functioning and electrical feedback from sensors during ignition. Once the burner achieves full operation within its chamber, the control module ramps up thermal output to match heat demand levels calculated from the water flow rate.

This rapid fire-up which takes only seconds eliminates delays between running hot water and achieving the set temperature. The precision monitoring also adjusts the burner output to account for flow fluctuations and keep hot water supply consistent. This superior automation and responsiveness ensure hot water on tap the moment it’s required.

Water is Heated as It Flows Through

The water passes through a copper heat exchanger, extracting heat as it travels through the coils before exiting from the unit. The heat exchanger is designed for rapid heating, bringing water up to temperature quickly.

Maintaining the Set Temperature

High performance continuous flow systems utilise powerful microprocessors running advanced modulating algorithms for controlling thermal output. Water temperatures can be maintained within a 1-2 degree tolerance of settings for safe and consistent supply.

Most units dynamically adjust burner firing rates multiple times per second to account for flow and pressure changes in real-time. This constant precision helps stabilise outlet water temperature during temporary supply variations to prevent scalding. Sophisticated electronics combined with rapid reaction modulation valves provide exceptional accuracy in delivering water at the desired set point.

Shutting Off When Not in Use

As soon as the tap is turned off and water flow ceases, the unit immediately shuts down the burner. This on-demand operation means you never run out of hot water and do not pay to constantly reheat a tank.

Hot Water Solutions

As New Zealand’s hot water specialists, we’re familiar with every intricate detail of how to properly size, install, and maintain continuous flow systems. Please reach out anytime if you have questions or need assistance. Call us at 0800497658 or contact us through our website if you’d like help or have any questions.

At Hot Water Solutions, all we do is hot water!